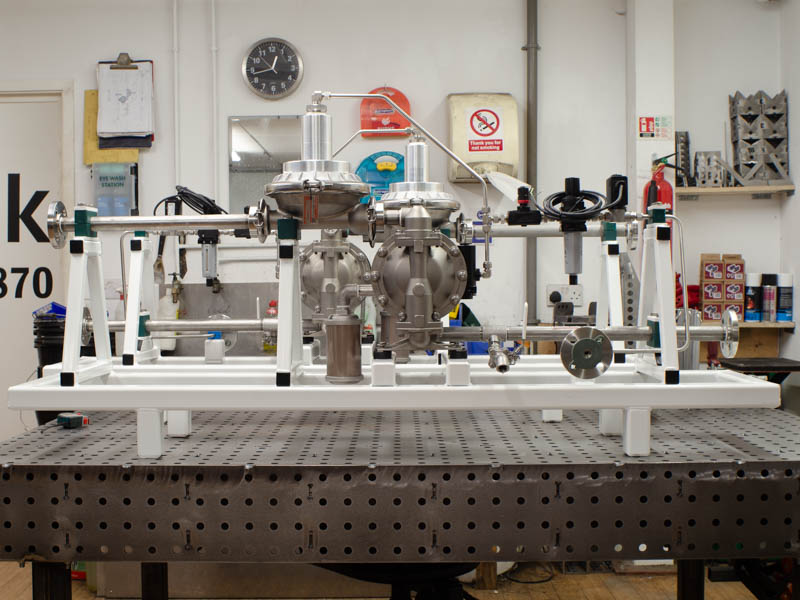

Skid fabrication for pumps on a fixed frame mounting & site portability

Mounting pumps on skids offers several practical and economic benefits that make them a preferred solution in industrial, commercial, and municipal applications. A skid provides a stable, pre-engineered platform that keeps the pump and related components aligned securely fixed in place. This improves reliability by reducing vibration, misalignment, and premature wear on bearings and seals, and eases both the strain and making pipe work connections.

Because the pump package is assembled and aligned to suit your needs, installation time in the field is significantly reduced—contractors simply position the skid, make the necessary piping and air connections, and the system is ready for commissioning. This not only speeds up deployment but also minimizes the risk of installation errors.

Because the pump package is assembled and aligned to suit your needs, installation time in the field is significantly reduced—contractors simply position the skid, make the necessary piping and air connections, and the system is ready for commissioning. This not only speeds up deployment but also minimizes the risk of installation errors.

Skid-mounted pump systems also support easier maintenance and long-term operability. With all key components arranged on a single base, technicians have better access for inspection, servicing, and replacement of parts. The controlled layout simplifies troubleshooting and ensures that future maintenance doesn’t disturb alignment. Additionally, skids can incorporate auxiliaries such as control panels, sensors, strainers, and instrumentation, creating a complete, self-contained system. For operations that may need to relocate equipment—such as temporary installations, mining sites, or construction projects—skids provide mobility and reusability, allowing pumps to be moved and redeployed with minimal effort. Overall, skid mounting enhances durability, efficiency, and life-cycle cost savings.

Manufactured in our workshop for your needs

|

|

|

|

|